In a recent excavation along the National Highways A428 Black Cat to Caxton Gibbet improvement project, archaeologists from the Museum of London Archaeology (MOLA) uncovered two Roman wells.

The discovery of these wells, dating back to the early Roman period (CE 43-410), provides insight into the ingenuity and adaptability of Roman engineering, as well as the occasional failures that even the Romans, renowned for their construction prowess, had to overcome.

The excavation took place at a settlement on the border of Cambridgeshire and Bedfordshire, which had evolved from a quiet farmstead in the Middle Iron Age (around 350 BCE) into a bustling center of industrial activity by the early Roman period (CE 43-150). The site revealed evidence of extensive metalworking, carpentry, and woodworking activities, indicating a well-organized industrial hub within a large, gated enclosure. The discovery of the two wells demonstrates both the importance of water supply to the settlement and the trial-and-error methods employed by the Roman builders.

The first of the two wells, located just outside the gated enclosure, was an impressive feat of engineering, reaching a depth of about 8.5 meters (28 feet)—equivalent to the height of a modern two-story house. Despite the effort invested in its construction, the well’s walls were not adequately secured, leading to a catastrophic collapse just before it could be completed. This collapse buried a wooden ladder inside, which had been used by the workers, but fortunately, no human remains were found, indicating that no one was harmed during the incident.

MOLA project manager Simon Markus commented on the collapse: “As we discovered when we first started our excavations here, the clay literally peels away from the more compacted earth and stone. We’ve all done a bit of DIY that hasn’t quite gone to plan, but this was a failure of Roman engineering on an industrial scale. A lot of effort would have gone into digging this well, which they then had to completely abandon.”

Undeterred by their initial failure, the Roman settlers quickly learned from their mistake. About 20 meters (65 feet) away from the first site, they began work on a second well, this time inside the enclosure. The new well was slightly shallower, at 6.5 meters (21 feet) deep, and featured significant design improvements to prevent another collapse. Unlike the first well, this one was carefully lined with wooden boards to reinforce the walls and prevent the surrounding clay from caving in. Additionally, a layer of cobblestones was placed at the base to filter the water, showcasing an understanding of engineering principles that aimed to provide a cleaner water source.

Markus noted the improvements, stating, “We can sympathize with the original well diggers because excavating these required as much careful design and effort as building them. This time, they used wooden boards to support the structure, and it worked.”

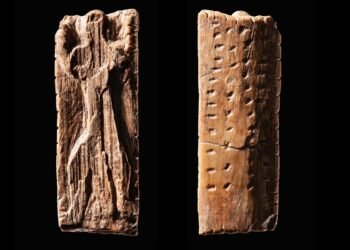

Alongside the cobblestone filter, the well contained various wooden scraps, including branches, woodchips, and off-cuts from planks. Some of the larger pieces of wood even bore decorative carvings such as horizontal lines and crosses, suggesting that they were initially intended for other purposes, possibly recycled from old furniture. This finding points to a substantial woodworking industry that was not merely for local use but likely involved wider trade networks.

Archaeologists also discovered evidence of a Roman road at the southern edge of the site, which they believe could have connected the settlement to major Roman routes. This road would have facilitated the transport of goods and materials to larger settlements like Godmanchester and nearby Roman countryside estates, indicating the settlement’s integration into a broader economic system.

The discovery of these two wells offers a rare glimpse into the practical challenges and innovative solutions of Roman engineers operating in Britain nearly 2,000 years ago.

More information: Museum of London Archaeology (MOLA)