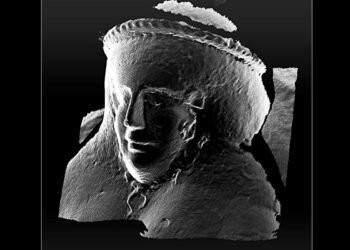

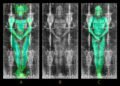

A team of historians and engineers at Auburn University has revived a piece of Renaissance-era prosthetic technology by employing modern 3D printing, offering a glimpse into the lives of amputees in 16th-century Europe. The focal point of their research is the Kassel Hand, an iron mechanical prosthetic believed to be German and perhaps 500 years old. It is one of only about 35 mechanical hands from Renaissance Europe that have survived.

The interdisciplinary collaboration, known as the Kassel Hand Project, was in operation from June 2023 to May 2025. It was not only about reconstructing this artifact, but also about developing a model for the use of 3D-printed replicas in an effort to better understand the day-to-day lives of premodern amputees. The team stated that prosthetic artifacts are extremely fragile and rare. At the heart of the project were the intertwining goals of finding new ways to study these artifacts and share them widely.

Directed by Dr. Heidi Hausse and mechanical engineer Dr. Chad Rose, the Auburn team used computer-aided design (CAD) software to create digital models of the Kassel Hand’s internal mechanisms. The replica was 3D-printed using polylactic acid (PLA), a durable and accessible plastic resin compatible with consumer-grade printers. The result was a functional model that enabled researchers to simulate real-life tasks such as gripping objects. Despite being made of plastic rather than iron, the prosthetic hand was able to lift approximately 20 pounds during laboratory tests.

The project did have a setback, however, during a public demonstration at the University of Alabama Birmingham. Within minutes, the main release lever—designed to unlock the fingers of the hand—suddenly broke due to user mishandling.

The engineering team traced the problem to the lever design, where people could press it too far, putting too much stress on the plastic. They adjusted the housing on the lever to reduce its motion range—a change that also enhanced the historical accuracy of the replica. The historians produced a step-by-step instructional video to help users use the prosthesis properly.

A week after the incident—dubbed “the Birmingham Break” by the team—they tested the improved model in a classroom at Auburn University. With four of the modified replicas and the help of the new instructional video, the demonstration was perfect.

The project was supported by Auburn University’s Creative Work and Social Impact Scholarship Funding Program and a Public Engagement Grant from the Renaissance Society of America. It also benefited from collaborative advice from experts like Dr. Jacob Baum, Dr. Gerald Stark, and clinical partners at Alabama Artificial Limb & Orthopedic Service Inc.

The team has now released the 3D model files to the public, so that this one-time elite piece of Renaissance technology can be used by anyone with a consumer-level 3D printer. The broader purpose is to begin discussing how people and technology have engaged in the past and how they engage today.

The project emphasizes that prosthetic technology is not simply a matter of mechanical innovation—it is a matter of human experience. By reconstructing a tool that had once belonged to an unknown 16th-century amputee, the Auburn team brings back a fragment of that person’s world.

More information: The Kassel Hand Project / The Conversation

Disclaimer: This website is a science-focused magazine that welcomes both academic and non-academic audiences. Comments are written by users and may include personal opinions or unverified claims. They do not necessarily reflect the views of our editorial team or rely on scientific evidence.

Comment Policy: We kindly ask all commenters to engage respectfully. Comments that contain offensive, insulting, degrading, discriminatory, or racist content will be automatically removed.

This project was directed by Heidi Hausse and Chad Rose. No person named Whitney E. L. Morgan is associated with the team. Where did that name come from?

Thank you for your comment and for pointing that out. It was an error on the author’s part and has now been corrected. We appreciate your help in keeping the information accurate.