While archaeologists have long known that people living in parts of Iran were experimenting with metal production around 5,000 years ago, exactly how early craftspeople transformed raw copper ore into usable metal has remained difficult to reconstruct, most surviving objects from the time are rare and fragile, and the debris left behind from smelting—blocks of hardened slag—has often proved too complex to study without sectioning. A new study, however, has introduced a method that allows researchers to peer inside these ancient remnants in unprecedented detail.

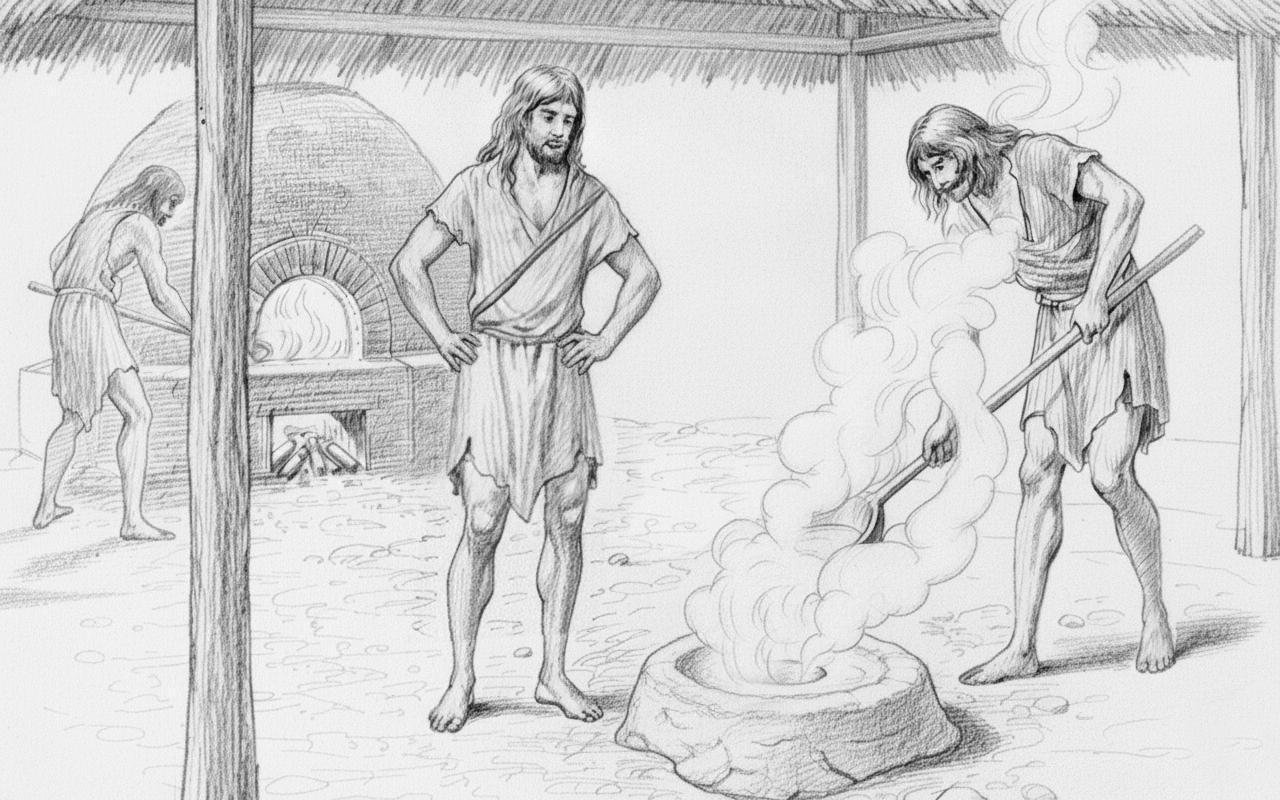

These researchers focused on slag recovered from Tepe Hissar, an Early Bronze Age settlement in northern Iran that flourished between approximately 3100 and 2900 BCE. The site is considered one of the earliest centers of organized metalworking, long-distance trade, and specialized craftsmanship in the region. By studying slag from this settlement, researchers hoped to clarify how some of the world’s first metallurgists managed the demanding process of smelting copper and early bronzes.

These researchers focused on slag recovered from Tepe Hissar, an Early Bronze Age settlement in northern Iran that flourished between approximately 3100 and 2900 BCE. The site is considered one of the earliest centers of organized metalworking, long-distance trade, and specialized craftsmanship in the region. By studying slag from this settlement, researchers hoped to clarify how some of the world’s first metallurgists managed the demanding process of smelting copper and early bronzes.

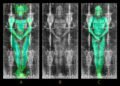

To do this, the team employed industrial X-ray computed tomography, more familiar to medical clinics than to the field of archaeology, to generate high-resolution 3D images of the interior of the slag. The scans showed a network of pores, cracks, and droplets of different materials, as well as subtle variations in density that indicated how the molten mixture had behaved as it cooled. This allowed the researchers to identify the most informative sections of each piece before any cuts were made, a major improvement over the guesswork that often comes with destructive sampling.

Once sectioned, the slag was analyzed using traditional archaeological X-ray fluorescence, X-ray diffraction, and scanning electron microscopy techniques. Such methods confirmed the presence of primary smelting phases, including magnetite and fayalite, with copper sulfide droplets, but also revealed how elements such as arsenic migrated or transformed within the slag over time. Some features included small arsenide compounds and secondary minerals formed through burial and corrosion, which helped explain earlier debates about arsenic’s role in early Iranian metallurgy.

The CT scans also revealed internal microenvironments that had formed over millennia, creating tiny pockets where new minerals were able to form as the slag interacted with soil, moisture, and dissolved ions. These secondary precipitates include calcite, atacamite, and scorodite, providing clues about local environmental conditions and the chemical pathways that shaped the slags after they had been discarded.

These techniques together have yielded a far more complete understanding of the smelting process than either approach would provide alone. The noninvasive scans preserved the artifacts while guiding more precise sampling, and the destructive methods supplied the chemical detail that CT imaging cannot capture on its own. All this together revealed how copper droplets were trapped inside the slag, how gases formed voids during high-temperature reactions, and how arsenic behaved both in primary smelting conditions and in long-term burial environments.

The study represents one of the first systematic uses of CT scanning in the investigation of ancient metallurgical waste. By creating digital 3D archives of each artifact and exposing features hidden deep within the slag, the method opens new possibilities for studying early technologies without damaging irreplaceable materials. This integrative approach—drawing on metallurgy, geochemistry, corrosion science, and thermodynamics—may help resolve longstanding questions about prehistoric copper production not only at Tepe Hissar but across the broader ancient world.

Disclaimer: This website is a science-focused magazine that welcomes both academic and non-academic audiences. Comments are written by users and may include personal opinions or unverified claims. They do not necessarily reflect the views of our editorial team or rely on scientific evidence.

Comment Policy: We kindly ask all commenters to engage respectfully. Comments that contain offensive, insulting, degrading, discriminatory, or racist content will be automatically removed.